HOW DO YOUR BRAKES WORK?

Everyone knows brakes cause your car to stop, but exactly what are brakes? How do brakes work? How have they changed over time?

Modern car braking systems are remarkably complex pieces of electronics and engineering, a far cry from the drum brakes of yesteryear. Understanding the components and how they work will help you manage your braking system maintenance and repairs in the future.

The automotive experts at Goodyear Brakes offer some tips for understanding your vehicle’s braking system, as well as advanced solutions for addressing any issues. The new line of Goodyear Brakes provides premium quality brake bundles, calipers, rotors, brake pads and all the hardwarefor today’s most popular vehicles, from daily drivers to SUVs as well as light trucks. This brake line is backed by a national warranty, decades of production experience and one of the best-known names in automotive excellence. The Goodyear Brakes product lineup offers the ideal solution for almost every braking need – whether drivers are looking to save money on their vehicle repairs, upgrade their performance or restore their perfect car.

Brakes: A Brief History

Brakes are actually older than cars themselves. The earliest wooden block brakes were used to control horse-drawn carriages in the 19th century. A wooden block brake is exactly what it sounds like: a piece of wood attached to a lever. When something pushes the lever, the wood piece blocks the carriage-wheel. Wooden block brakes became obsolete with the introduction of rubber tires in the late 1800s, as the block would simply wear the tires down.

Mechanical Drum Brakes—the Earliest Modern Braking System

Mechanical drum brakes—pioneered by Maybach and Renault—are the direct forerunners of modern braking systems. In drum brakes, brake shoes exert radial pressure inside of the drum assembly. The resulting friction causes the car to slow down. To this day, many cars have drum brakes for their rear wheels.

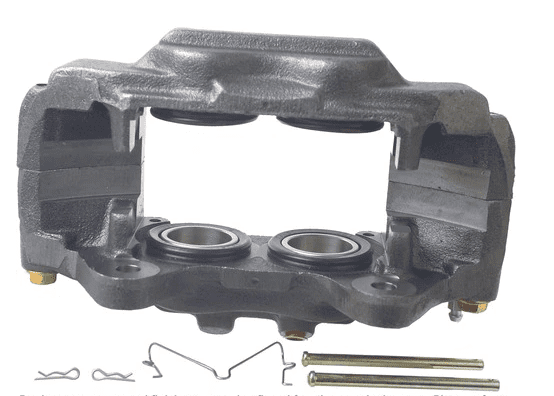

Fixed-Position Caliper

Brake Pad

Early Disc Brakes

As early as 1902, the UK’s Lanchester Motor Company pioneered the successor to drum brakes: disc brakes. While they were safer and more efficient than drum brakes, early disc brakes had a number of shortcomings. Early disc brakes were very expensive and made of copper. When engaged, they’d emit a harsh screeching noise. Also, the dusty, rough surfaces of 20th century roads quickly wore out early disc brakes. It wasn’t until the 1950s that disc brakes became cheap and reliable enough to fit a wide variety of vehicles. To this day, the cost difference between disc and drum brakes makes many budget cars feature drum brakes on their rear axles.

How Do Disc Brake Systems Work?

Most modern braking systems are disc-braked. When the brake is engaged, disc pads push up against the disc rotors, causing friction to slow the car down. A number of parts in the braking system work together to make this happen.

WHAT ARE THE KEY COMPONENTS OF A MODERN BRAKING SYSTEM?

Car brakes aren’t a single entity—they’re an entire system of components that work in tandem to ensure your car comes to a rapid halt after you step on the brake pedal. Here are some of the main components in your braking system:

- Brake pedal

- Master brake cylinder

- Brake lines

- Brake calipers

- Brake pads

- Brake rotors

- Braking fluid

- The anti-lock braking system (ABS)

How does the braking process work?

When you floor the brake pedal, a number of things take place in quick succession to generate friction, stop the wheels from spinning, and brings your car to a halt. Let’s take a look at the braking process step-by-step.

- The brake pedal is pressed. Brake pedals are designed to be force multipliers. Through mechanical leverage, they amplify the force of your leg by an order of magnitude. This force is then transmitted to the master cylinder.

- A metal rod connects the pedal to the master brake cylinder, which is filled with hydraulic brake fluid. Flooring the brake pedal causes a piston in the master brake cylinder to depress.

- Once the piston drops, pressure builds up in the cylinder and forces the brake fluid to move through the brake lines and toward the calipers on each axle.

- Transmitting hydraulic pressure, the calipers on both sides of each axle force the brake pads onto the brake rotors. The friction between the pads and the rotors slows your car down.

- As your car stops, friction from the braking process converts the kinetic energy of your car in motion into a great amount of heat. Brake pads are made of a special material to withstand high temperatures—up to 1000 degrees F in certain cases.

Caliper & Rotor

What is ABS?

The ABS is an electronic system that prevents your wheels from locking up. Before ABS was implemented, drivers had to control braking force manually. If you exerted too much braking force, the wheels would lock up and cause your car to skid dangerously. ABS systems continually monitor and regulate braking pressure to prevent pressure from exceeding the brake lock threshold. The likelihood of skidding is also reduced as the ABS works in tandem with your hydraulic disc braking system to ensure that your car stops in time, keeping you safe.